Sep. 03, 2019

With the popularity of SPC lock floor, everyone constantly knows the advantages of this new type of flooring, how do we choose affordable high quality SPC lock floor? Next, we will identify the advantages of the SPC lock floor for everyone.

First, how is the SPC lock floor made?

The SPC lock floor is made of polyvinyl chloride (divided into pure new material, mixed material, recycled material), calcium powder (classified with grade of stone powder) and solvent. High temperature pressure hot stamping film and PVC wear layer, after cooling treatment, then going on UV process (determine the anti-fouling performance of the floor and the non-discoloring performance after exposed in the sun), the final cutting and slotting process (partially determines the floor lock strength, bearing tension) ), finally packaging.

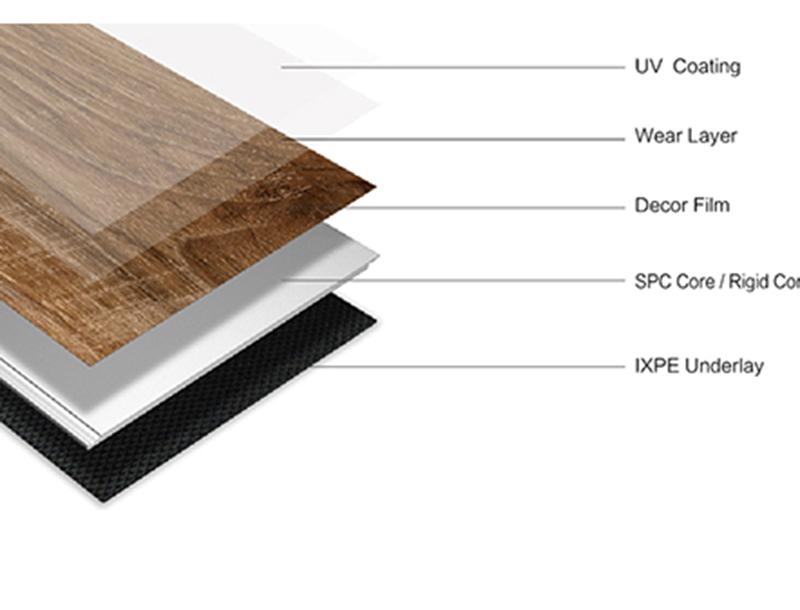

Second, the layered diagram of the SPC lock floor

Third, explain some of the three misunderstandings in common understanding

1. "Flame retardant" is not "burning"

Have to take a lighter to burn the PVC floor, see if you can burn it, it is not fireproof when burned, it is flame retardant. In fact, the national requirements for the fire rating of PVC floor to reach the Bf1-t0 level, according to the national standard non-combustible materials designated as fire A grade, such as stone, tile and so on. The technical standard of Bf1-t0 flame retardant standard is cotton ball with a diameter of 10mm. The alcohol cotton ball is placed on the PVC floor and burned naturally. After the cotton ball is burned out, the diameter of the burnt PVC floor mark is measured, such as less than 50mm, is the Bf1-t0 flame retardant standard, instead of watching "burning can not burn."

2. "Wearing" is not "with a sharp weapon will not scratch"

When asked about the service life and wear resistance of PVC flooring, take out a sharp knife or key and other sharp tools, and scratch the surface of the PVC floor. If it is scratched, it is considered not to be wear-resistant. In fact, the national abrasion resistance test of PVC floor is not simply using a sharp tool to scratch the surface. Using a flat-bottomed sanding disc,the test floor is polished under the condition of 1Kg of pressure. After the rotation and grinding, the surface of the floor is wear-resistant. The layer is worn to expose the number of revolutions of the substrate. The number of revolutions of this node is an indicator to measure the wear resistance of PVC flooring. For example, the number of laminate floor turns is 1500 rpm. Therefore, the abrasion resistance of PVC flooring is determined by the national testing agency.

3. "Smell smelling with the nose" is not "not environmentally friendly"

The PVC material itself is formaldehyde-free. PVC flooring is also not allowed to use formaldehyde in the production process. The qualified PVC floor should be 100% formaldehyde-free. It may have the smell of aromatics and additives, and will not hurt people and it doesn't make you feel uncomfortable.

Fourth, the benefits of the SPC lock floor.

1. Waterproof and flame retardant

SPC flooring is 100% waterproof and is ideal for kitchens, bathrooms and basements. The flame retardant properties allow the flame to extinguish automatically without toxic or harmful gases.

2. Health, safety and environmental protection

Say goodbye to formaldehyde, mold and bacteria. The product has been tested with 179 different types of hazardous substances and other chemicals. Unlike ordinary flooring, there is no plasticizer inside, so it is more environmentally friendly.

3. Heat and cold resistance

Our SPC flooring does not curl at most temperatures or environments. SPC flooring can withstand a temperature difference of -75 ° C to 80 ° C. The dimensional stability is very good. According to the EN434 standard, the shrinkage ratio was 0.002%, and the crimp ratio was 0.2 mm.

4. Quality and strength

It is more powerful than WPC flooring and laminates, and the price is right! SPC is used with a silica core instead of wood stone to form a flooring material made of a waterproof component. SPC flooring is stronger, more durable and more stable than ordinary LVT flooring. It also has an improved lock connection system. This product has excellent resistance to indentation (scratch resistance and abrasion resistance) as well as anti-overflow and anti-fouling properties. It is resistant to abrasion, mildew or mildew, and has an anti-slip function that allows you to install it anywhere, even in combination with underfloor heating systems. It has five layers of wear protection as well as XPE, EVA and CORK liners. These pads are glue-free and the SPC floor is safe and easy to use, allowing the room to be muted.

Five, the seven steps to identify the advantages and disadvantages of the spc lock floor

1, look at the color: mainly look at the "spc substrate" color, the color of the pure material is beige, the mixture is gray, cyan, white, the recycled material is gray black, black. In this case, the cost can be divided into many levels.

2, feel the touch: spc substrate feels delicate, there is a sense of moisture. The recycled materials and the mixture have a dry feel and no water sensation. After the two pieces are spliced, the flatness and the fit are good.

3, smell odor: This is a very poor individual will have a little smell, most of them contain recycled materials and mixes can still be done without odor.

4, light (transparency): mobile phone flashlight is attached to the floor, there is good light transmission, the material and recycled materials are opaque. Or the light transmission is very poor.

5, the thickness: the condition is best to use the caliper or micrometer to measure the thickness of the floor, the actual thickness is about 0.2mm more than the nominal thickness is normal range, for example: the regular manufacturer according to the production standard marked 4.0 thickness, with a caliper or micrometer The measurement should be around 4.2, because the wear layer and the thickness of the UV layer are added. If the measured value is 4.0, then you actually buy a thickness of 3.7--3.8, which is commonly known as cutting corners. Other links we can't see can be imagined to what extent this manufacturer can do.

6, break the lock: the edge of the floor buckle (that is, the part of the lock leakage), forcefully break off the lock, the strength of the unqualified floor is not very big, it is easy to break off the lock.The lock of the qualified floor is strong enough.

7. Tear: This is not easy to operate. It is necessary to collect several pieces of merchant samples, and carry out the destruction and combing in the corner part. The color film layer and the SPC substrate are partially broken and torn, and the color film layer and the substrate are bonded. Strength, this decision is easy to peel in the next few years of use. The bonding strength of pure new materials is the largest, followed by others. If it can't be operated, it doesn't matter. Basically, through the appeal step, it is not bad to judge the quality of the merchant product.